Following a talk by Mark Hemming, Regional Director of Amazon in February, the Business Degree students were given the opportunity to visit the local fulfilment centre at Amazon in March. The initial impact of the size of the building (about 10 football pitches) was amazing to see. Once inside the safety instructions were delivered and then each person was given a headset and transmitter so that they could hear the tour leader clearly above the noise in the centre.

The first question posed to the group was to consider the way items are stored on the shelves. This was fascinating, as you walked along the shelves you would see protein powder next to nappies next to books. It all looked very haphazard, but in fact it was organised – in a random fashion. Each item is logged as it enters the building and then put into any available space on the shelves but technology means that the system knows where every item is in the building. Pickers then use scanners to tell them which aisle and shelf to go to, to pick the products that have been ordered. Pickers will also pick products for a range of orders but not fulfil every item and it is at a later stage when the Wranglers take items from the boxes and put orders together. The packing team are given instructions from the technology as to which box size to use to pack the order, the exact length of tape is dispensed to seal the box and a bar code is affixed. This bar code holds details of the name and address to send the parcel, the weight that the parcel should be and which carrier will take it, e.g. Royal Mail or Hermes etc. At the next stage the address label is affixed by a machine which works on compressed air and then the parcel makes its way to the correct channel dependent on the carrier. Any errors, for example if the box weight was incorrect for the items enclosed, or the label was not affixed correctly then the system would throw the boxes out of the system and they would each be checked separately.

The students found the visit very informative as to how such a market leader is able to deal with so many products and to distribute them effectively and were able to relate this to what they had learnt in the module Logistics and Distribution.

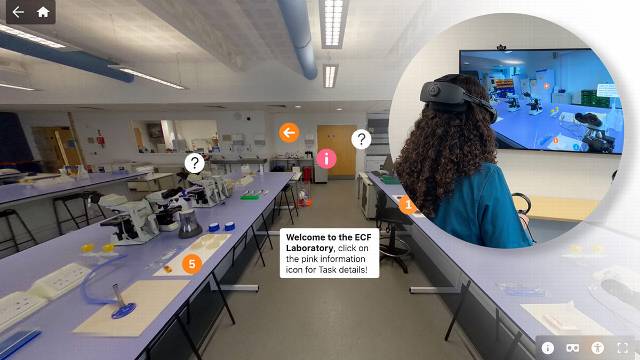

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday