Mike Rudge, who studied BSc (Hons) Food and Consumer Studies at Harper Adams University, featured on the BBC's Supermarket Secrets aired on 24th April. Mark now works for IPL International Procurement and Logistics as a technologist after graduating in 2015 and joining a graudate scheme with the same company.

Mike is responsible for all technical elements of ASDA's supply chain for whole head top fruit and citrus. He gave an insight into his day-to-day role as a technologist, starting with the moment fruit arrives in the packing facility and the processes it goes through. This time it was satsumas that had just arrived from South Africa, transported for 30 days by sea freight in chilled containers.

To check that the fruit will be in top condition when it reaches customers' homes, it has to go through several checks for mould. After a check for visible mould, a sample of the delivery will go into a mould incubator called the Shelf Life Room to check if there is any mould that can't yet be seen. The conditions are warm and moist, to replicate those of a typical home where the fruit will be stored by the customer.

Further tests on the satsumas enable damaged or at risk fruit to be removed. This is done by using a UV fruit-scanning machine. The UV light shows up any tangeratin which indicates the fruit is damaged and will likely grow mould, these satsumas are then removed. Fruit that is damaged and has mould growth will go for further processing.

Watch Supermarket Secrets and see Mike at 24:00.

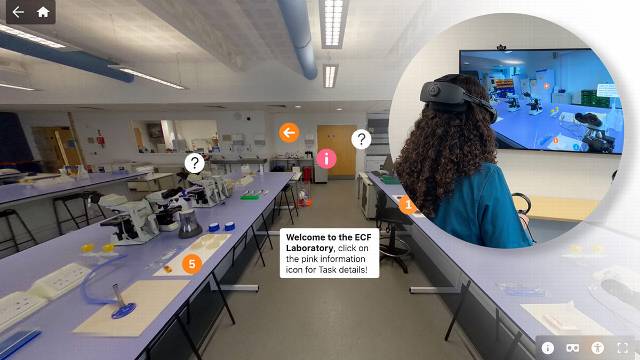

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday