A group of students from Harper Adams University’s Engineering department have been working closely with the Small Robot Company on a project examining the building and commissioning process of a robot.

The Small Robot Company is on a mission to reimagining farming to make food production sustainable using robotics and artificial intelligence to monitor, treat and plant crops.

The students worked on the Tom robots for their project over the last six months. The robot autonomously maps the field it is working on to build an understanding of where every plant is located and what needs to be implemented to achieve optimal performance.

Rhian Griffith, from the Small Robot Company was the point of contact for the Harper students and worked closely with the team to develop a test rig for the machine.

“We had been discussing developing the test rig for a few months but were struggling to find the time and resources to do so. When the group project was proposed, it seemed like the perfect opportunity to do so as it could be done in parallel to our other projects and we were able to act as a customer instead.”

As part of the project, students had to deliver their final handover, for which they produced and presented a presentation showing their findings and their finished product.

“The final handover was an onsite visit at Harper, where me and my team came to receive a presentation summarising the entire project, including the assessing the initial requirements, deliverables and presenting the project outcome. Although we'd had several design reviews leading up to the handover, this was when we saw the final design completed which very exciting.

“It's been great and somewhat of a learning experience for me and my team - working with a group of young engineering students, where the overall goal is to try and get the best out of the students and make sure the project works for them, as much as me, was quite tricky sometimes.

“I think the project would have further developed their technical engineering skills that they would gain from the degree but mostly this group project would have developed their teamwork, presentation, communication, technical information delivery and possible system design skills.”

Luke Waldram, a 4th Year MEng Automotive Engineer (Off Highway) at Harper Adams University was one of the students involved in the project.

He said: “This project truly tested our capabilities from start to finish and was far from easy. There was no hand holding throughout the process and it truly was solely guided by us as students running the project. Working with the Small Robot Company was an absolute pleasure from start to finish!”

Working with people in industry is valuable opportunity that students at Harper experience through their placement year – as well as through projects such as this.

Luke added: “Exposure to working with other engineers in industry has actually allowed us to think and act like real engineers do – this has meant that we have developed some key initial skills which most graduates won’t have even begun to develop yet.

“This really gives us an upper hand as we are industry-ready on day one without having to be hand-held. Having some modules such as the Engineering Group Project, based in industry, is crucial and it’s something all universities should be doing but many aren’t! Once again giving Harper Adams students the upper hand on day one!”

“The main skills that have been developed over the course of this module - and the whole year- have definitely been leadership and responsibility skills. Having to own the work you produce for a client in industry truly changes your mindset on how things should be done and allows you to put everything important you’ve learned into practice without and hand-holding from lecturers. It’s the students’ project, it’s run how the students deem fit, there’s a sense that the safety net is no longer there so you not only want to get things right but strive to achieve the best.”

Speaking about the final handover process, Luke said: “The final handover meeting went very well for us, the client was very pleased with the final product and the way we delivered the project from the beginning to end and they now are looking into actually getting the factory acceptance test rig we designed produced so they can use it!”

After the handover meetings were finished, Rhian and the team were given a tour of our facilities and campus, including our Hands Free Farming project.

Rhian said: “I had a wonderful day at Harper. The formalities and handover took up about half of the visit, after that the students showed me around the engineering facilities, the farm and the hands-free farming equipment.

“I got the chance to discuss other projects with some of the staff and the students showed me some of their other work that they complete as part of their degree.”

And Luke added: “Studying at Harper Adams is honestly the best decision I ever made. The lecturers in the engineering department are brilliant, they are always there to support you and help you to thrive.

“It’s hard work, don’t get me wrong, but there is plenty of opportunities to let your hair down and get stuck in with a club or a society. I’ve made some great friends at Harper, many of which I will no doubt cross paths with again in industry.”

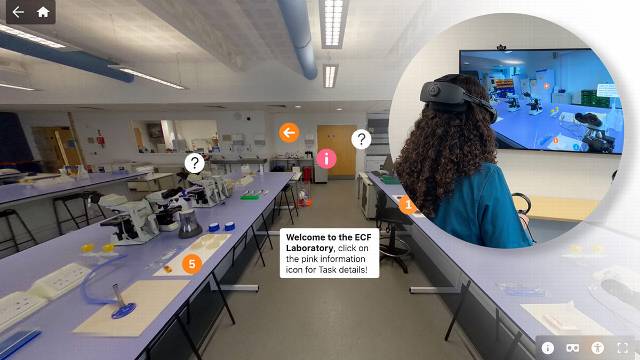

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday

Blog: Veterinary Medicine students step into immersive 360° laboratory

At Harper & Keele Veterinary School, students are stepping beyond the traditional microbiology bench and into an immersive 360° labo …

Posted

Yesterday